The technique exploits the capillary effect – the rise of a liquid through a narrow space – to coat droplets in a composite shell containing oil-loving and hydrophobic particles. It offers the ability to tune the shell thickness over a wide range, allowing the encapsulation of droplets of different sizes. The study was published in Nature Communications.

Droplets are important in a variety of fields. “In microreactors, droplets can be used to create different reaction environments or mix different chemicals. In drug delivery systems, droplets can be used to deliver drugs or other agents to specific tissues or organs. In crystallisation studies, droplets can be used to control the growth of crystals. And in cell culture platforms, droplets can be used to grow cells in a controlled environment, which can help to improve cell viability and proliferation,” said lead researcher Rutvik Lathia, PhD student at the Centre for Nano Science and Engineering (CeNSE), IISc, in a press statement.

However, there are several challenges in using such droplets. They are vulnerable to contamination from the ambient environment, the ease and success of a particular process depends a lot on the surface they’re dropped on, and they can vanish into thin air pretty fast. While encapsulating droplets with liquids or solids that don’t mix with the droplets (like water droplets inside an oil shell) is a plausible solution to avoid these issues, making a shell that is hardy, continuous and has an adjustable thickness at a super tiny scale has proven elusive so far, the statement added.

To address these challenges, Prosenjit Sen, Associate Professor at CeNSE, and his team have developed a new capillary force-assisted cloaking method to trap droplets within colloidal particles and liquid-infused surfaces.

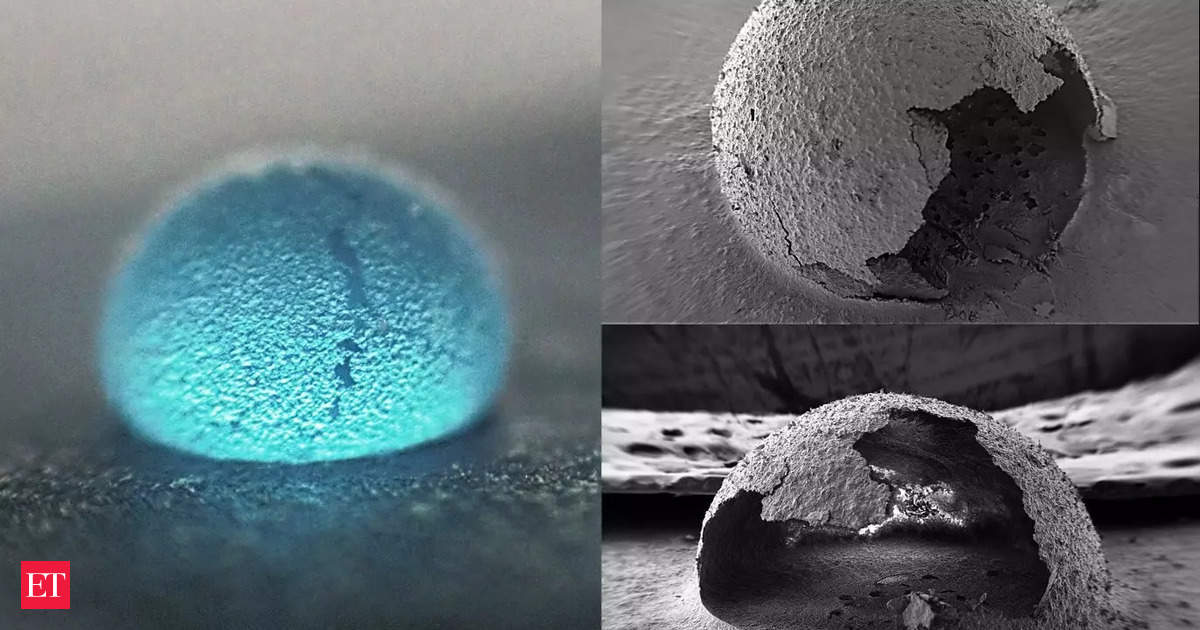

First, they carefully coated droplets with small hydrophobic and oil-loving beads, turning them into what they call Liquid Marbles (LM). When these LM are kept on oil-infused surfaces, capillary forces kick in, allowing the oil to rise up into tiny pores created between individual beads. These beads play a crucial role in promoting and stabilising the formation of a liquid film around the droplet, effectively encapsulating it. The researchers were also able to use wax instead of oil to create a solid shell by adjusting the temperature. Such encapsulation reduced the evaporation rate of droplets by up to 200 times, increasing the lifetime of these droplets, the team found. They were also able to adjust the shell thickness flexibly over a wide range – from 5 μm to 200 μm. This allowed them to accommodate droplets with volumes ranging from 14 nL to 200 μL. “Our method of encapsulating droplets introduces a multitude of new opportunities in the realm of droplet-related applications. The tunable nature of the shells, both solid and liquid, allows for precise control over various parameters, making it versatile for applications in chemistry, biology, and materials science,” Sen said.

The researchers used these coated droplets to grow single crystals successfully. They could also use the coated droplets for biological applications such as 3D cell culture and growing yeast cells in the lab with improved success rates.

“So far, we are able to make wax-based solid capsules and oil-based liquid capsules,” Sen added. “Now, we are looking into newer materials to form capsules with different properties that could enhance tunability further, such as polymer-based capsules.”